Stainless Steel Seamless Pipe

Categoría:

Stainless Steel Pipe

Stainless Steel Seamless Pipe

Stainless Steel Seamless Pipe Description

By definition, seamless tubes are completely homogenous tubes, the properties of which give seamless tubing more strength, superior corrosion resistance, and the ability to withstand higher pressure than welded tubes. This makes them more suitable in critical applications in harsh environments, but it comes with a price.

Product Parameters

|

Product Name |

Stainless Steel Seamless Pipe |

|

|

Type |

Steel Pipe |

|

|

Outer diameter |

Round Tube |

4mm-200mm |

|

Square Tube |

10*10mm-100*100mm |

|

|

Rectangular Tube |

10*20mm-50*100mm |

|

|

Wall Thickness |

0.6mm-6.0mm |

|

|

Length |

1-6 meters, Length can be customized |

|

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

|

Surface |

Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. |

|

|

Scope of Application |

Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. |

|

|

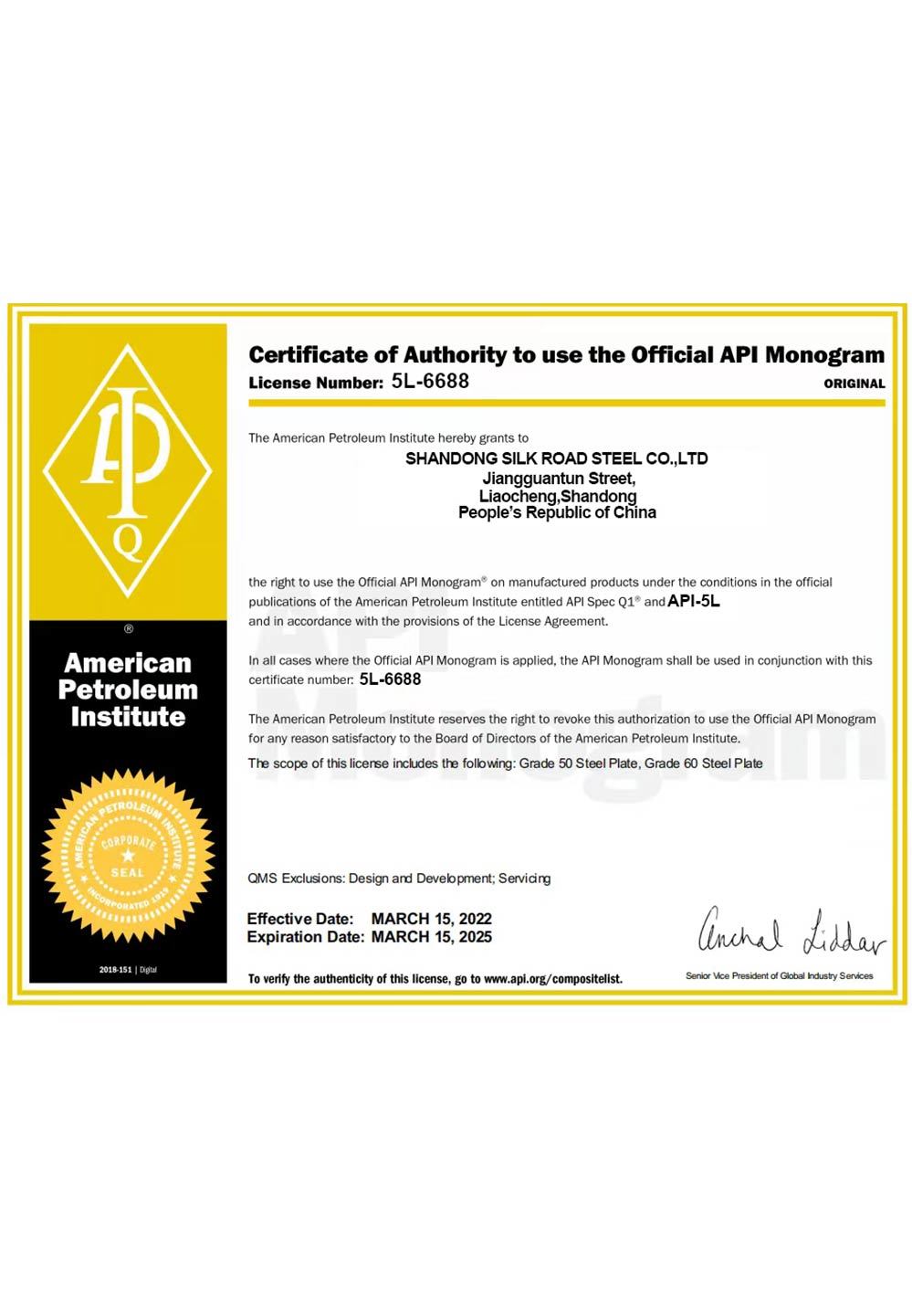

Certificate |

ISO, SGS, BV, etc. |

|

|

Production Technology |

Hot Rolling, Cold Rolling |

|

|

Edge Processing |

Edging, Trimming |

|

Stainless Steel Seamless Pipe Manufacturing

Knowing that distinction can also help in determining which tubing is best for a given application, welded or seamless. The method of manufacturing welded and seamless tubing is evident in their names alone. Seamless tubes are as defined – they do not have a welded seam. The tubing is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form. The billets are first heated and then formed into oblong circular molds that are hollowed in a piercing mill. While hot, the molds are drawn through a mandrel rod and elongated. The mandrel milling process increases the mold’s length by twenty times to form a seamless tube shape. Tubing is further shaped through pilfering, a cold rolling process, or cold drawing.

Stainless Steel Seamless Pipe Benefits

● Stronger

● Superior corrosion resistance

● Higher pressure resistance

Stainless Steel Seamless Pipe Applications

● Oil and gas control lines

● Chemical injection lines

● Below sea safety valves

● Chemical processing plant steam and heat trace bundles

● Fluid and gas transfer

|

|

GB |

JIS |

ASTM |

UNS |

KS |

DIN |

BIS |

AS |

CNS |

|

| Austenitic Stainless Steel | ||||||||||

|

1 |

12Cr17Mn6Ni5N |

SUS201 |

201 |

S20100 |

STS201 |

1.4372 |

10Cr17Mn6Ni4N20 |

201-2 |

201 |

|

|

2 |

12Cr18Mn9Ni5N |

SUS202 |

202 |

S20200 |

STS202 |

1.4373 |

- |

- |

202 |

|

|

3 |

12Cr17Ni7 |

SUS301 |

301 |

S20200 |

STS301 |

1.4319 |

10Cr17Ni7 |

301 |

301 |

|

|

4 |

06Cr19Ni10 |

SUS304 |

304 |

S30400 |

STS304 |

1.4301 |

07Cr18Ni9 |

304 |

304 |

|

|

5 |

022Cr19Ni10 |

SUS304L |

304L |

S30403 |

STS304L |

1.4306 |

02Cr18Ni11 |

304L |

304L |

|

|

6 |

06Cr19Ni10N |

SUS304N1 |

304N |

S30451 |

STS304N1 |

1.4315 |

- |

304N1 |

304N1 |

|

|

7 |

06Cr19Ni9NbN |

SUS304N2 |

XM21 |

S30452 |

STS304N2 |

- |

- |

304N2 |

304N2 |

|

|

8 |

022Cr19Ni10N |

SUS304LN |

304LN |

S30453 |

STS304LN |

- |

- |

304LN |

304LN |

|

|

9 |

10Cr18Ni12 |

SUS305 |

305 |

S30500 |

STS305 |

1.4303 |

- |

305 |

305 |

|

|

10 |

06Cr23Ni13 |

SUS309S |

309S |

S30908 |

STS309S |

1.4833 |

- |

309S |

309S |

|

|

11 |

06Cr25Ni20 |

SUS310S |

310S |

S31008 |

STS310S |

1.4845 |

- |

310S |

310S |

|

|

12 |

06Cr17Ni12Mo2 |

SUS316 |

316 |

S31600 |

STS316 |

1.4401 |

04Cr17Ni12Mo2 |

316 |

316 |

|

|

13 |

06Cr17Ni12Mo2Ti |

SUS316Ti |

316Ti |

S31635 |

- |

1.4571 |

04Cr17Ni12MoTi20 |

316Ti |

316Ti |

|

|

14 |

022Cr17Ni12Mo2 |

SUS316L |

316L |

S31603 |

STS316L |

1.4404 |

~02Cr17Ni12Mo2 |

316L |

316L |

|

|

15 |

06Cr17Ni12Mo2N |

SUS316N |

316N |

S31651 |

STS316N |

- |

- |

316N |

316N |

|

|

16 |

022Cr17Ni13Mo2N |

SUS316LN |

316LN |

S31653 |

STS316LN |

1.4429 |

- |

316LN |

316LN |

|

|

17 |

06Cr18Ni12Mo2Cu2 |

SUS316J1 |

- |

- |

STS316J1 |

- |

- |

316J1 |

316J1 |

|

|

18 |

022Cr18Ni14Mo2Cu2 |

SUS316J1L |

- |

- |

STS316J1L |

- |

- |

- |

316J1L |

|

|

19 |

06Cr19Ni13Mo3 |

SUS317 |

317 |

S31700 |

STS317 |

- |

- |

317 |

317 |

|

|

20 |

022Cr19Ni13Mo3 |

SUS317L |

317L |

S31703 |

STS317L |

1.4438 |

- |

317L |

317L |

|

|

21 |

06Cr18Ni11Ti S |

SUS321 |

321 |

S32100 |

STS321 |

1.4541 |

04Cr18Ni10Ti20 |

321 |

321 |

|

|

22 |

06Cr18Ni11Nb |

SUS347 |

347 |

S34700 |

STS347 |

1.4550 |

04Cr18Ni10Nb40 |

347 |

347 |

|

| Duplex Stainless Steel | ||||||||||

|

1 |

- |

SUS329J1 |

329 |

S32900 |

STS329J1 |

1.4477 |

- |

329J1 |

- |

|

|

2 |

022Cr23Ni5Mo3N |

- |

S32205 |

F60 |

- |

1.4462 |

- |

2205 |

2205 |

|

|

3 |

022Cr25Ni7Mo4N |

- |

S32750 |

F53 |

- |

1.4410 |

- |

2507 |

2507 |

|

| Ferritic Stainless Steel | ||||||||||

|

1 |

06Crl3Al |

SUS405 |

405 |

S40500 |

STS405 |

1.4002 |

04Cr13 |

405 |

405 |

|

|

2 |

022Cr11Ti |

SUH409 |

409 |

S40900 |

STS409 |

1.4512 |

- |

409L |

409L |

|

|

3 |

022Cr12 |

SUS410L |

- |

- |

STS410L |

- |

- |

410L |

410L |

|

|

4 |

10Cr17 |

SUS430 |

430 |

S43000 |

STS430 |

1.4016 |

05Cr17 |

430 |

430 |

|

|

5 |

10Cr17Mo |

SUS434 |

434 |

S43400 |

STS434 |

1.4113 |

- |

434 |

434 |

|

|

6 |

022Cr18NbTi |

- |

- |

S43940 |

- |

1.4509 |

- |

439 |

439 |

|

|

7 |

019Cr19Mo2NbTi |

SUS444 |

444 |

S44400 |

STS444 |

1.4521 |

- |

444 |

444 |

|

| Martensitic Stainless Steel | ||||||||||

|

1 |

12Cr12 |

SUS403 |

403 |

S40300 |

STS403 |

- |

- |

403 |

403 |

|

|

2 |

12Cr13 |

SUS410 |

410 |

S41000 |

STS410 |

1.4006 |

12Cr13 |

410 |

410 |

|

|

3 |

20Cr13 |

SUS420J1 |

410 |

S42000 |

STS420J1 |

1.4021 |

20Cr13 |

420 |

420J1 |

|

|

4 |

30Cr13 |

SUS420J2 |

- |

- |

STS420J2 |

1.4028 |

30 Cr13 |

420J2 |

420J2 |

|

|

5 |

68Cr17 |

SUS440A |

440A |

S44002 |

STS440A |

- |

- |

440A |

440A |

|

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

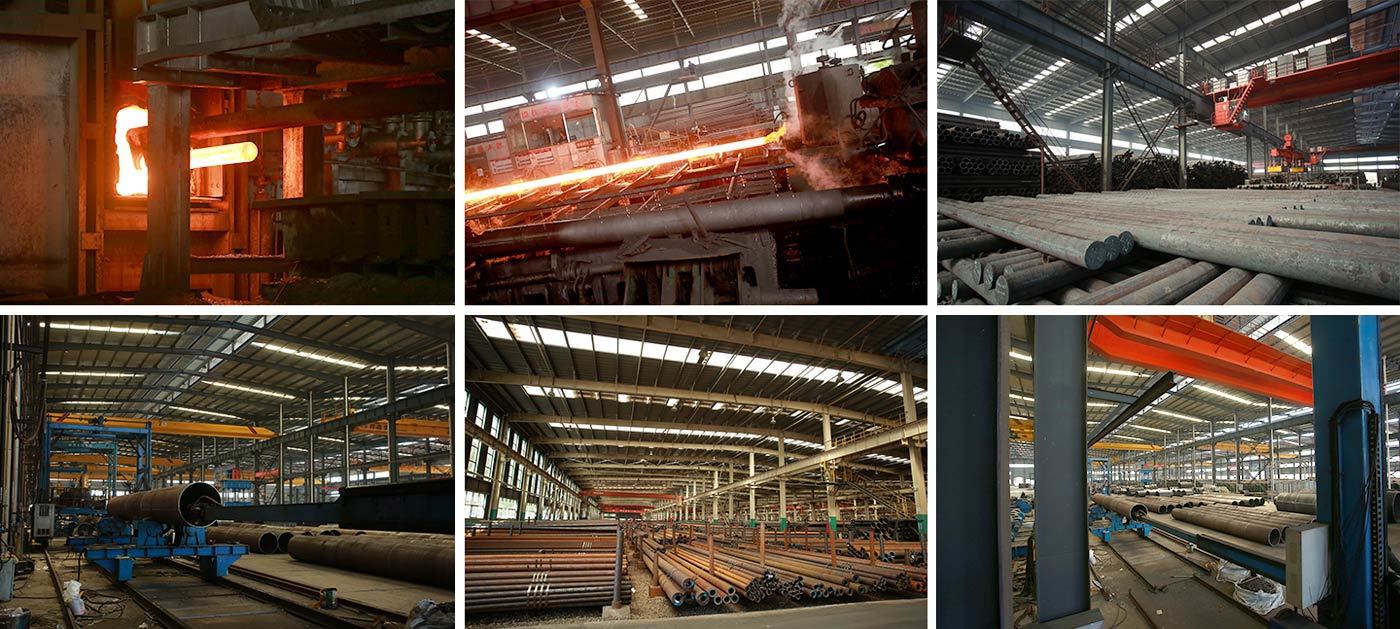

FÁBRICA

Somos un fabricante de acero con una larga historia y reputación de excelencia. Desde nuestro establecimiento en 2018, siempre nos hemos comprometido a proporcionar a los clientes productos de acero y servicios de procesamiento profundo de acero de la más alta calidad y más eficientes para satisfacer sus necesidades en diversos proyectos de ingeniería.

VISITAS DE CLIENTES

En el desarrollo futuro, continuaremos defendiendo los conceptos de profesionalismo, integridad, innovación y unidad, mejorando continuamente la calidad del producto y los niveles de servicio, y brindando a los clientes productos y servicios de acero más eficientes y de alta calidad. ¡Esperamos trabajar con usted para crear un futuro mejor!

APLICACIÓN

Nuestra gama de productos cubre varias especificaciones de placas de acero, secciones de acero, tuberías de acero, etc., que son ampliamente utilizadas en la construcción, puentes, maquinaria, barcos, petróleo, gas natural y otros campos. Siempre nos adherimos a una estricta gestión de calidad para garantizar que cada producto cumpla con los estándares nacionales y los requisitos del cliente.

Honor

PRODUCTOS RELACIONADOS