Electrolytic Tinplate Coil (ETP)

Categoría:

Bobina de la hojalata

Electrolytic Tinplate Coil (ETP)

Electrolytic Tinplate Coil (ETP) Description

Tin plating has been widely used in the electronic industry as a protective and solderable coating for electronic components, wires, printed circuit boards, and integrated circuit blocks due to its excellent corrosion resistance and solderability.

The application of electroplated tin is very extensive. Tin has advantages such as corrosion resistance, color resistance, non toxicity, easy brazing, softness, low melting point, and good ductility. Through special pre-treatment processes, a strong, bright, dense, uniform, and continuous alloy coating is formed on the surface of composite materials.

Product Parameters

Product Name | Electrolytic Tinplate Coil (ETP) |

Thickness | 0.18mm-0.50mm |

Width | 260mm-980mm |

Length | Support customization |

Tin Coating | General: 2.8g or 5.6g, can be produced according to your needs |

Substrate Type | MR / SPCC / L / D |

Reference Standard | GB/T 2520, JIS G3303, JIS G3315, DIN EN 10202, DIN EN 10203 |

Surface State of Tinplate

Surface State | Features |

Light Surface | Electroplated tin smooth raw material strip after melting treatment to obtain the glaze,Smooth surface with very fine grindstone pattern |

Stonetextured Surface | Electroplating tin raw material with the glaze obtained after melting treatment,Grindstone pattern with certain direction |

Silvercolor Surface | Electroplating tin raw material with the glazed surface obtained after melting treatment, the surface is rough and dull |

Mattless Surface | The surface of the substrate is rough and dull, and the tin plating layer is not soft melting |

Substrate Type

Substrate Type | Introduction |

MR | The most general steel, steelmaking impurity residue less, excellent mechanical properties and corrosion resistance |

L | Used for the production of acidic contents (oranges, yellow peaches, pineapples, etc.), and the inner surface of the food cans for iron high corrosion resistance tinplate substrate steel, such tinplate is often calledKPlate |

D | Used to produce two pieces of high-processing tin plate substrate steel, such tin plate is often called.DIMaterial |

SPCC | Chinese characteristics, using ordinary hot rollingSPHCProduces, usually used for miscellaneous tank purposes. |

Coating Weight

Classification | Representation of Tin Coating Weight | Tin Plating Nominal Weight (g/m2) | Minimum Average Tin Plating Weight (g/m2) |

Equal Tin Plating (E) | 1.1/1.1 | 1.1/1.1 | 1.8 |

2.2/2.2 | 2.2/2.2 | 4.0 | |

2.8/2.8 | 2.8/2.8 | 5.0 | |

5.6/5.6 | 5.6/5.6 | 10.5 | |

Differentiated Tin Plating (D/A) | 2.2/1.1 | 2.2/1.1 | 2.0/0.9 |

2.8/1.1 | 2.8/1.1 | 2.25/0.9 | |

5.6/1.1 | 5.6/1.1 | 5.05/0.9 | |

2.8/2.2 | 2.8/2.2 | 2.25/2.0 | |

5.6/2.2 | 5.6/2.2 | 5.05/2.0 | |

5.6/2.8 | 5.6/2.8 | 5.05/2.25 |

Chemical Composition

No. | C | Si | Mn | S | P | Cu | Ni | Cr | Mo |

D | 0.12 | 0.03 | 0.6 | 0.05 | 0.02 | 0.2 | 0.15 | 0.1 | 0.05 |

L | 0.13 | 0.03 | 0.6 | 0.05 | 0.15 | 0.03 | 0.04 | 0.06 | 0.05 |

MR | 0.13 | 0.03 | 0.6 | 0.05 | 0.2 | 0.2 | 0.2 | 0.1 | 0.05 |

Mechanical Properties & Applications

Standard Name | Nominal Hardness HR30TS | Strong Yield MPA | Scope of Application |

T-1 | 49 | 230 /-50 | Drawing requirements, drawn ironing cans, nozzles, nozzles, closures |

T-2 | 53 | 245 /-50 | Ring and plug, dome, closure, shallow pull and special tank parts |

T-2.5 | 55 | 260 /-50 | Battery cell, small can cover and body |

T-3 | 57 | 275 /-50 | Cans and cans, large diameter caps, crown caps |

T-3.5 | 59 | 290 /-50 | Can body, closure and crown lid |

T-4 | 61 | 340 /-50 | Can body, closure and crown lid |

T-5 | 65 | 480 /-50 | Cans and cans |

Ordering Notes

The ordering elements for tin plating generally include: standard grade (including steel grade code, annealing method and other information such as MR T-3 CA), size (the default order is thickness * width * length, tin plating amount ((different thickness plating) Tin needs to add A/D as the marking line mark, if not, no marking line will be marked), surface, order quantity, etc.

When ordering tin plating, please confirm with our sales staff the end use, such as canbody, ends, twist off caps, crown cork, EOE, etc., as well as the contents, special contents such as milk powder, high protein food, mushrooms, fruits, etc.;

|

|

GB/T 2520 |

JIS G3303 |

ASTM A623M |

DIN EN10203 |

ISO 11949 |

|

T-1 |

TH50 SE |

T-1 |

T-1(T49) |

TS230 |

TH50 SE |

|

T-2 |

Se encuentra en TH52 |

T-2 |

T-2(T53) |

TS245 |

Se encuentra en TH52 |

|

T-2.5 |

TH55 SE |

T-2.5 |

T-2.5(T55) |

TS260 |

TH55 SE |

|

T-3 |

TH57 SE (en inglés) |

T-3 |

T-3(T570) |

TS275 |

TH57 SE (en inglés) |

|

T-4 |

TH61 SE |

T-4 |

T-4(T61) |

TH415 |

TH61 SE |

|

T-5 |

Se encuentra en TH65 |

T-5 |

T-5(T65) |

TH435 |

Se encuentra en TH65 |

|

DR7 |

H71 SE |

DR7 |

DR7(T71) |

TH520 |

H73 SE |

|

DR8 |

H73 SE |

DR8 |

DR8(T73) |

TH550 |

H73 SE |

|

DR9 |

H76 SE |

DR9 |

DR9(T76) |

TH620 |

H76 SE |

EMBALAJE Y ENVÍO

Los productos de la compañía se exportan a más de 70 países y regiones en el mundo, incluyendo Europa, América, Alemania, Corea del Sur, Indonesia, Bangladesh, etc. Tenemos nuestra propia flota de transporte con el transporte más conveniente y entrega oportuna.

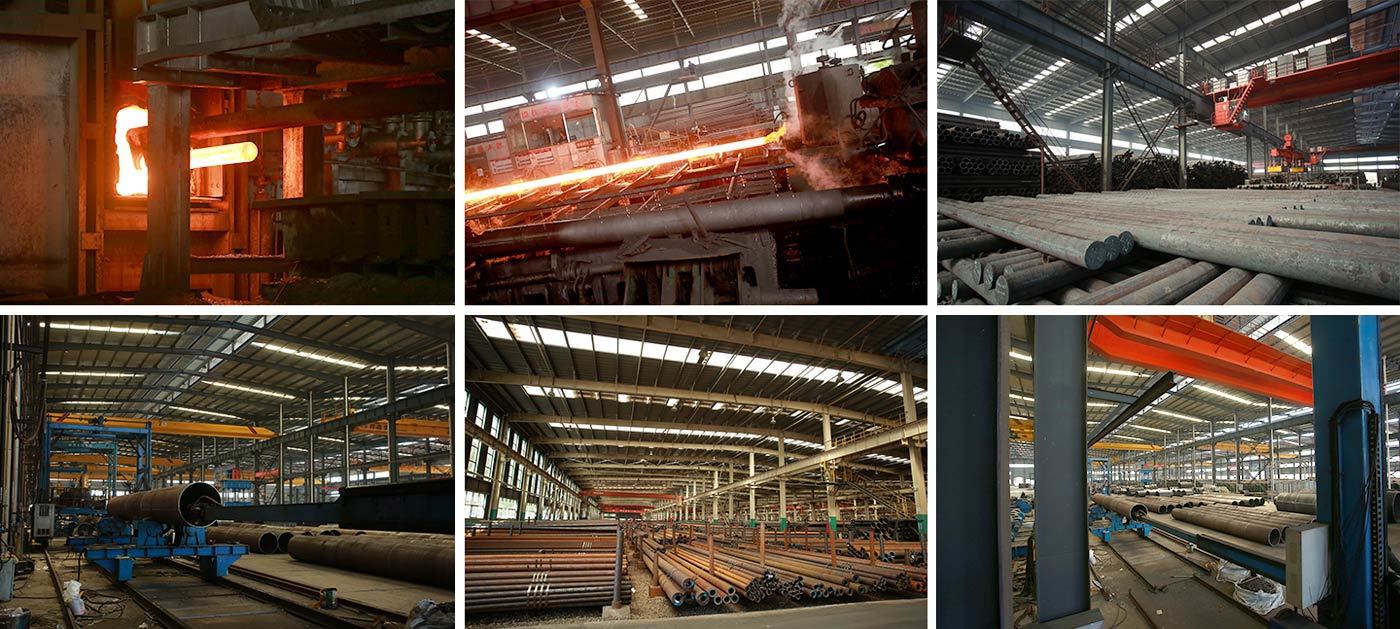

FÁBRICA

Somos un fabricante de acero con una larga historia y reputación de excelencia. Desde nuestro establecimiento en 2018, siempre nos hemos comprometido a proporcionar a los clientes productos de acero y servicios de procesamiento profundo de acero de la más alta calidad y más eficientes para satisfacer sus necesidades en diversos proyectos de ingeniería.

VISITAS DE CLIENTES

En el desarrollo futuro, continuaremos defendiendo los conceptos de profesionalismo, integridad, innovación y unidad, mejorando continuamente la calidad del producto y los niveles de servicio, y brindando a los clientes productos y servicios de acero más eficientes y de alta calidad. ¡Esperamos trabajar con usted para crear un futuro mejor!

APLICACIÓN

Nuestra gama de productos cubre varias especificaciones de placas de acero, secciones de acero, tuberías de acero, etc., que son ampliamente utilizadas en la construcción, puentes, maquinaria, barcos, petróleo, gas natural y otros campos. Siempre nos adherimos a una estricta gestión de calidad para garantizar que cada producto cumpla con los estándares nacionales y los requisitos del cliente.

Honor

PRODUCTOS RELACIONADOS